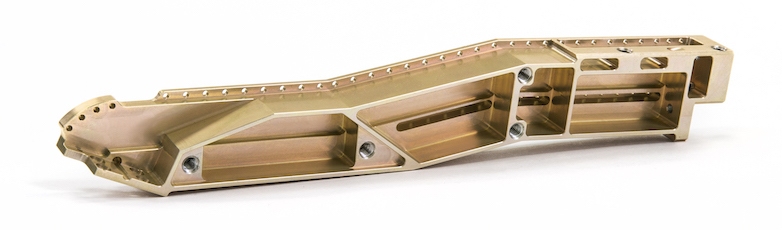

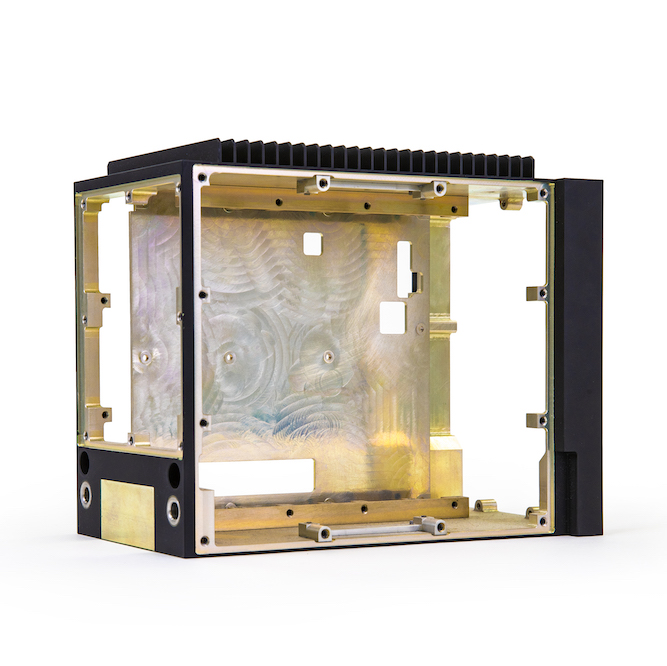

With nearly 50 DMG Mori Seiki machines and a highly experienced and talented staff, TL Machine offers a broad range of machining expertise and capability. Conveniently located in Southern California, we have access to a diverse supply of raw materials and outside processing. Our specialty is production machining, and we typically operate as the preferred manufacturing outsource partner to our customers from prototype to production. In addition to machining, we offer a broad range of value-added assembly as well. Many of the parts we produce are utilized in extremely critical Aerospace, Medical, and Energy applications. We enjoy top-tier ranking with major customers for Quality and On-Time Delivery.

CNC Milling

- DMG Mori Seiki

- 3-Axis Milling – 120” x 40” x20”

- (3m x 1m x 0.5m)

- 4-Axis Milling – 41” x 35” x 40”

- (1m x 0.9m x 1m)

- 5-Axis Milling – 28” x 20” x 20”

- (0.7m x 0.5m x 0.5m)

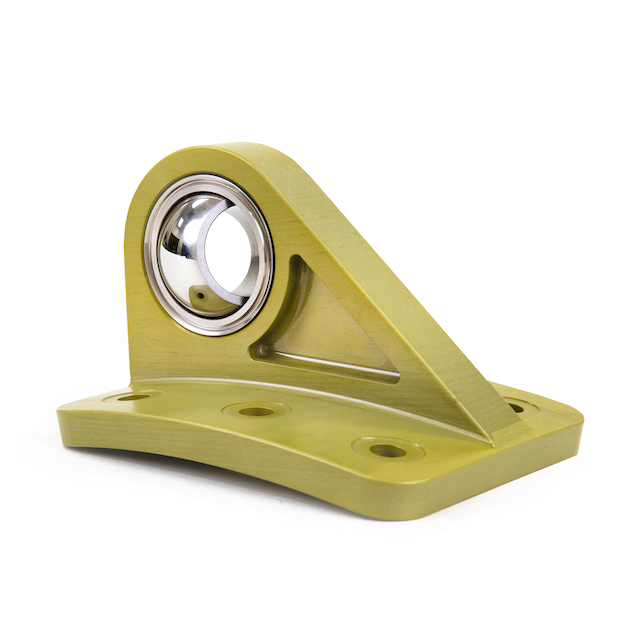

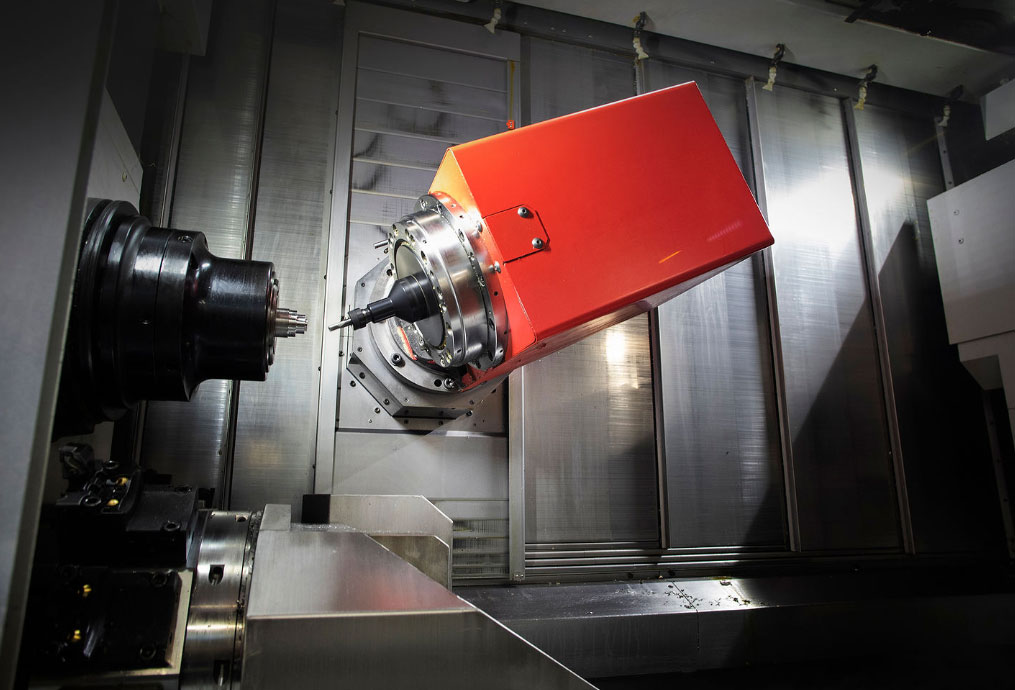

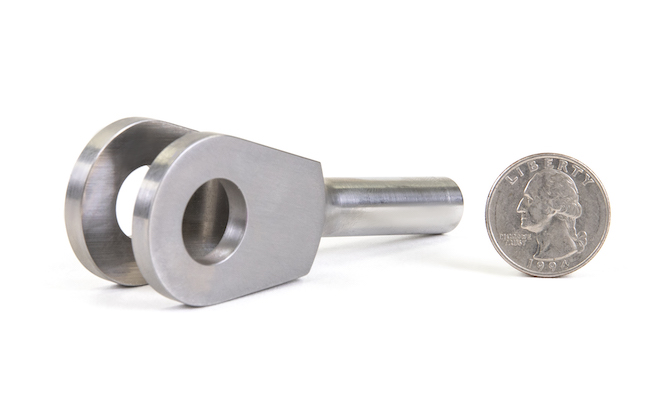

CNC Turning & Mill/Turn

- DMG Mori Seiki

- 4 and 5-Axis CNC Mill/Turn

- Up to 2.5” (63mm) Diameter Bar Feed)

- Screw Machines

- Materials range from Aluminum and Steel Alloys to Titanium and engineered plastics

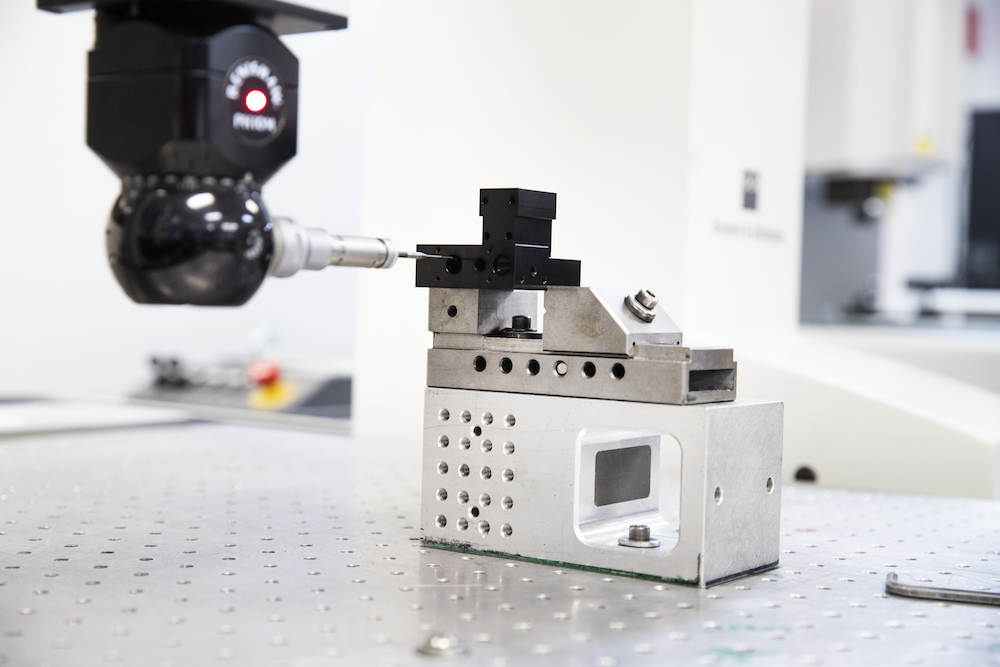

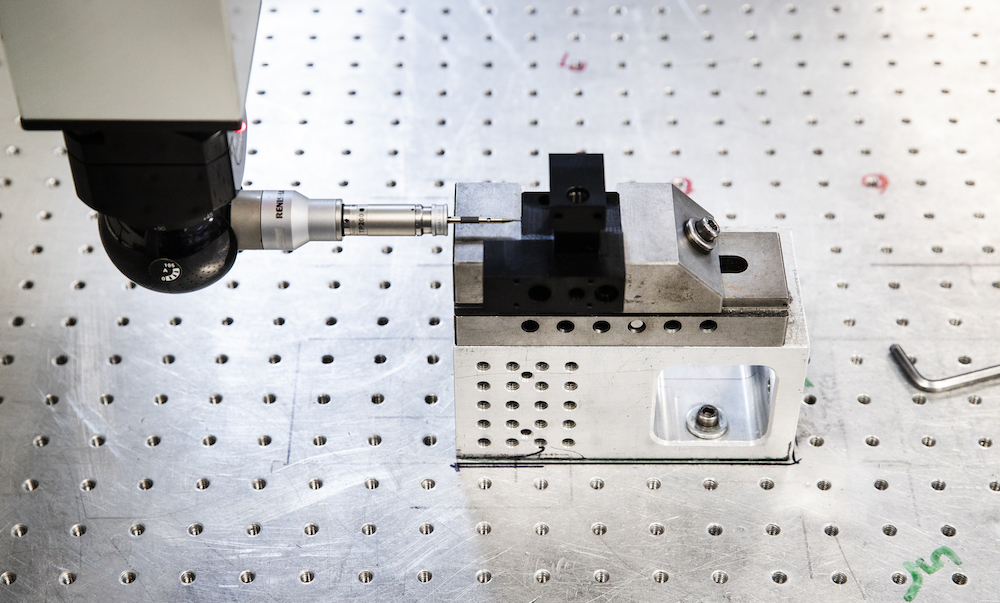

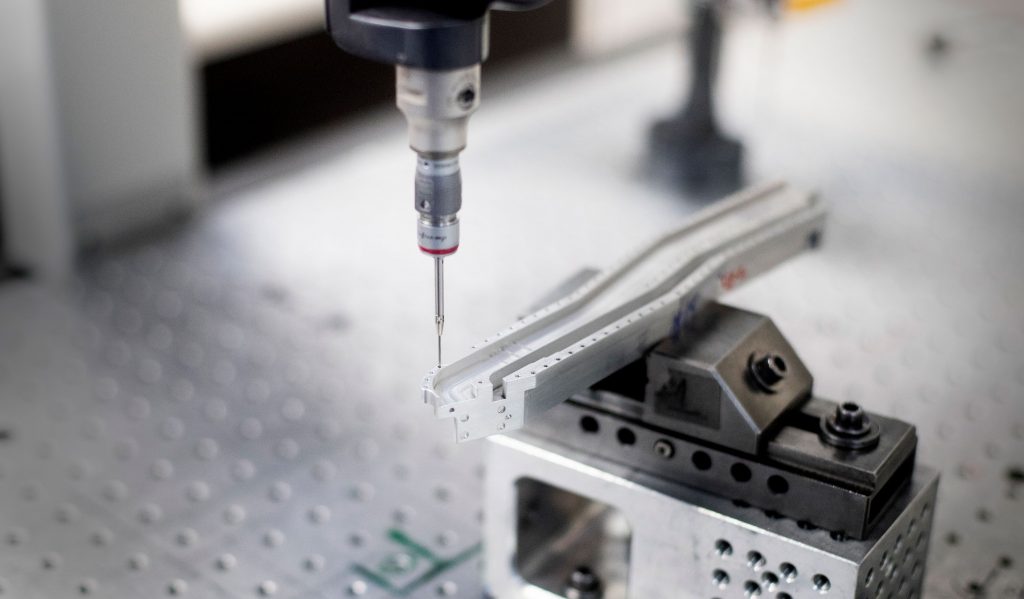

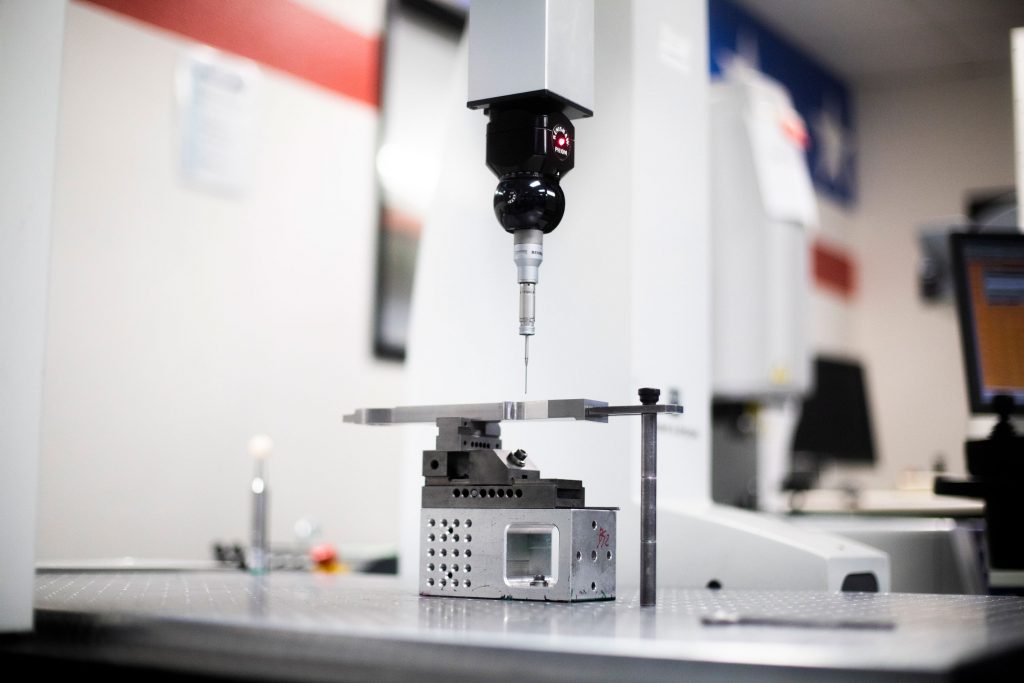

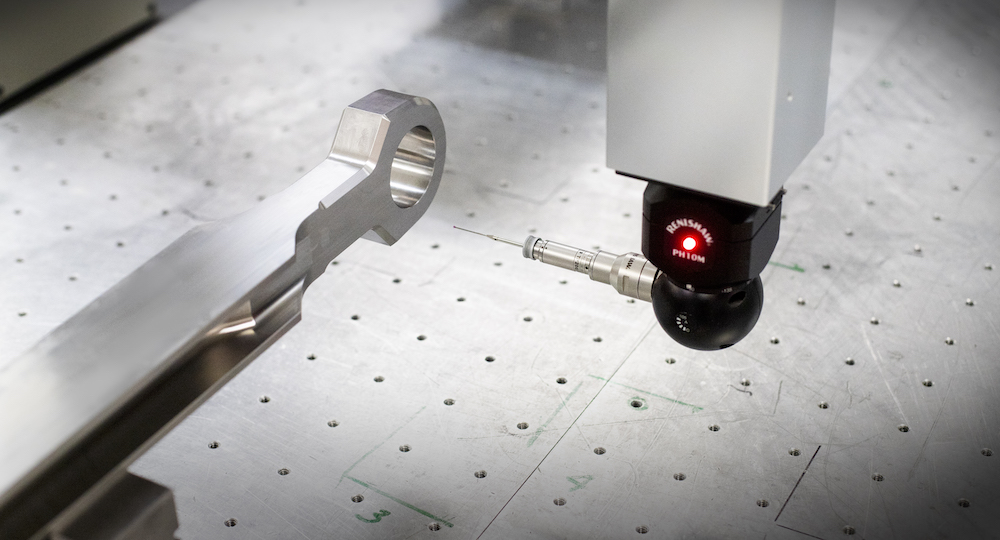

Quality & Inspection

- Temperature Controlled QC Lab

- 5 CMMs

- 2 Mitutoyo

- 3 Browne & Sharpe

- Large surface plate

- Full suite of calibrated hand tools

- AS9100 & ISO 9001 Certified by SCB